Measurement Technology for Quality Management in Automated Loading and Unloading

In order to guarantee a trouble-free production, a thorough incoming goods inspection of load carriers is required. This process may be placed by you either directly before the incoming of the goods or by the supplier before the outgoing of the goods.

The process is nearly the same and varies according to your individual specifications.

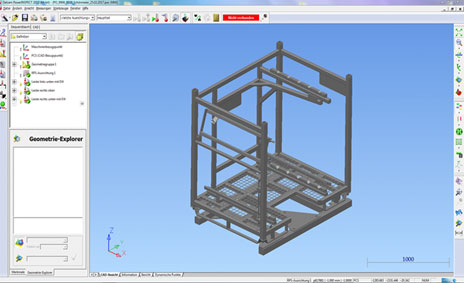

We compare the actual condition of the load carriers with the volume model (which represents the absolute target condition). For such purpose, only a current 3D file of the load carrier is needed. Any and all common formats, such as prt, AllCATPart, step, igs, etc., may be used.

The recording of geometry may be done directly at the load carrier or at a measured recording thereof (on a measurement table).

Especially in the case of series measurements, this saves an enormous amount of time. However, it is required if the centring recording is installed at the load carrier and / or not freely accessible as a result thereof.

Measurement with a 3D Volume Model

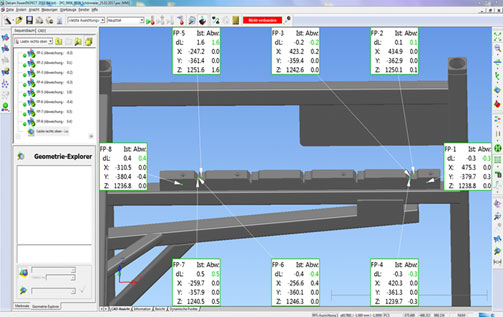

Our measurement processes are based on 3D measurement with a solid model. As already mentioned before, the actual condition of the object is compared to the absolute target condition in accordance with the CAD. This form of measurement is the most reliable and accurate form for tactile measurement as used by us.

In real-time, the camera transfers the position of the feeler to the 3D model. Therefore, you can immediately see where the special building components of the object are and can immediately rework them without having to leave the measurement. This saves time as – in comparison to the sole measurement of the target value – you do not have to search the points, in most cases using an acoustic signal.